Precision Machining

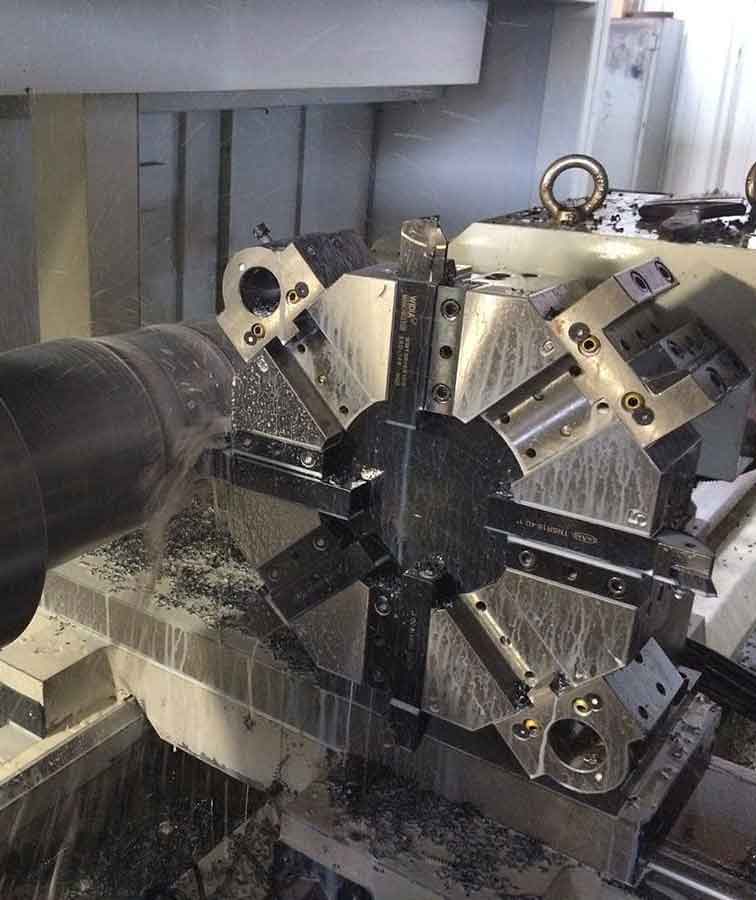

At General Machine, precision isn’t marketing fluff—it’s the expectation. Our shop just outside of St. Louis, has been turning out precision machining, heavy metal fabrication, and welding work for decades. If it’s too big, too complex, or too much for most shops, that’s usually when our phone rings.

We have the technical expertise for our CNC machines, but the knowledge and experience for our manual machines. When automation won’t cut it, we can manually machine your parts to get the specs you need.

Why Precision Machining Matters

In low volume production manufacturing and heavy equipment repair, “close enough” is the fastest way to cost yourself more time and money. Precision machining is about getting it right, every time, no excuses. Whether we’re boring, turning, or milling, our machinists blend old-school manual skill with modern CNC tooling to hit tight tolerances that keep your equipment moving.

Our Precision Machining Capabilities

- CNC & Manual Turning – For large and small components that demand accuracy.

- Boring & Milling – Tackling oversized parts most shops won’t touch.

- Drilling & Tapping – Clean, precise holes where and when you need them.

- Large-Part Machining – If your part doesn’t fit anywhere else, we’ve got room for it here.

- Custom Fabrication – One-off prototypes or repeat runs, built to spec.

- Low Volume Production – From tens to hundreds, we can make the parts you need.

- Welding & Repair– Strong, clean welds that keep repairs working long after the problem’s solved.

Let’s just say: if it’s made of metal and it needs machining, there’s a good chance we can do it—and do it better than the last guy.

Equipped to Handle

Your Precision Machining Orders

We have the best in top-line equipment allowing us to handle any precision machining requirements. Our CNC capabilities include:</br/></br/>

- Carlton 5’’ horizontal boring mill with over 17’ of horizontal capacity

- Doosan horizontal CNC mill with 78” X 114” of travel

- Akira-Seiki vertical mill with a 33’’ X 81’’ table

- Doosan vertical mill with a 22” X 41” table

- Atrump horizontal lathe that provides over 13’ of travel and a 30’’ swing

- Samsung horizontal lathe provides over 3’ of travel to align dimensions.

We also have manual equipment that includes small and large capacity lathes, mills, a vertical lathe, and most other machine shop essentials.